Share Article

For material handling managers and operators of forklift trucks alike, lithium-ion (Li-ion) batteries are becoming increasingly more popular for battery-powered electric vehicles. The primary reasons for this are that they don’t produce harmful emissions and they’re generally more energy-efficient than other available battery alternatives.Li-ion batteries are described as having a high energy density due to the lithium inside them being highly reactive. There are many different lithium-ion battery types on the market and each type has different properties depending on the application of the battery.

Read on to learn more about the functionality, features, and benefits of Li-ion batteries.

7 key considerations of lithium-ion batteries

1. Cell type

TCM lithium-ion battery cell types are prismatic in NMC (Lithium Nickel Manganese Cobalt Oxide) chemistry and are packaged in a metal casing. A primary feature of prismatic Li-ion batteries is that they offer pressure vents that function to alleviate internal pressure which works to avoid unpredictable explosions in a warehouse or on-site.

The cell modules are controlled by an advanced battery management system (BMS) which balances cell status, and measures existing energy levels, temperature, and so on. The BMS communicates this to the battery charger via CAN (Controlled Area Network), which is a standardised electronic communication vehicle that allows electronic devices to communicate efficiently without the need for extensive wiring.

In case of error or failure, the BMS will shut down the power to the truck in a safe way.

2. Operating temperatures

Temperature is a critical factor as it has the potential to significantly impact the performance and application of Li-ion batteries. As different temperature conditions can result in different or adverse effects, getting to know a range of temperatures in this application is important for ensuring your batteries, and therefore your forklifts, are safe and in full working order.

Ambient temperature with full performance:

- Battery charging/discharging average temperature range: 0⁰C to +40⁰C

- Battery storage temperature range: 0⁰C to +40⁰C

- Li-ion charger temperature range: 0⁰C to +40⁰C

Ambient temperature with permanently reduced capacity and/or performance:

- Battery charging/discharging temperature range: -28⁰C to 0⁰C and +40⁰C to +55⁰C

- Battery storage cell temperature range: -20⁰C to 0⁰C and +40⁰C to +45⁰C

All continuous applications, -28⁰C to 0°C, are cold store applications with particular specifications and require a bespoke design.

Get in touch with your local TCM dealer to find out more.

3. Charging systems

State-of-the-art Li-ion battery chargers are specifically designed to operate with the Li-ion battery product line. These batteries communicate with the battery management system via the CAN protocol. When the charger is connected to the battery, the BMS will shut down the truck’s vehicle control module (VCM) in around 5 seconds, before charging is automatically started.

As previously mentioned, Li-ion batteries offer maximum energy efficiency which is realised through a number of features:

- State-of-the-art charging systems: energy efficiency which is realised via:

- a pioneering multi-resonance converter technology

- an intelligent activation management system for the charging modules when operating under

- a partial load significantly reduced standby power consumption

- Standby mode: this significantly reduces power consumption.

- Intelligent activation management system: this functions for the charging modules operating under a partial load.

- Encapsulated cooling: heat sinks are used when batteries/power semiconductors are being cooled. Along with cooling the Li-ion batteries, encapsulated cooling also works to keep dust and grime to a minimum.

- ‘In-service’ operations: chargers will continue to charge with reduced output even after the individual modules have been removed.

- Mounting: Li-ion batteries are intended to be fitted on a wall with brackets for optimum safety and efficiency. These brackets are typically included in your package upon purchase.

4. Understanding charging times

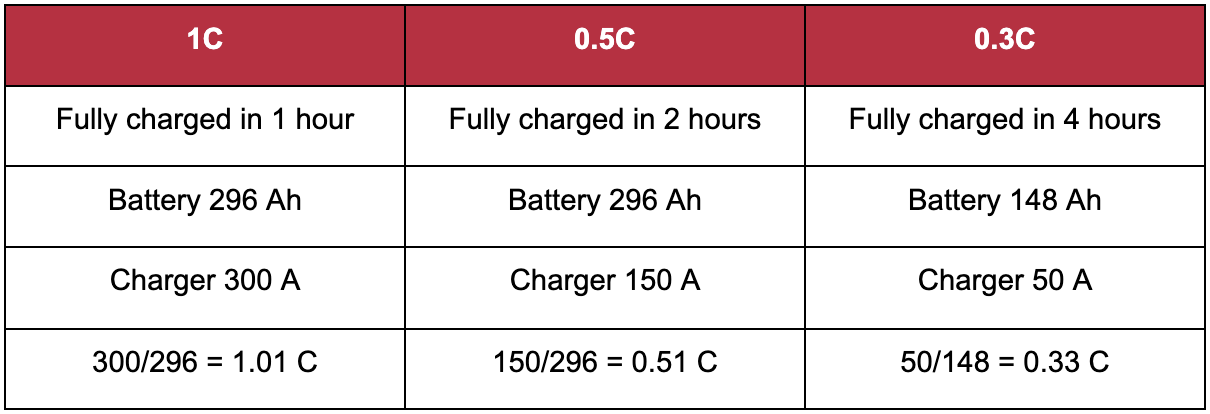

A key advantage of lithium-ion batteries is that they’re able to offer rapid charging. However, this can be temperature-dependent. At a normal ambient temperature of +25⁰C, the batteries can be charged at 1C – which means fully charged in one hour.

‘C’ refers to the rate of charge and discharge. The capacity of a battery is typically rated at 1C, which means that a fully charged battery rated at 1Ah should provide 1A for one hour, for example.

For additional context, take a look at this table for some examples of alternative charging times:

5. Opportunity charge

Opportunity charging is a method wherein batteries are able to stay inside the forklift truck for multiple shifts while being charged. This is a standard procedure for Li-ion batteries. The battery management system protects the battery from harmful deep discharge as it will automatically alarm at a low state of charge (SOC) – reactively cutting the hydraulic lift system – and will later shut down the VCM truck computer to protect the truck, battery and operator.

When the Charger is connected to the battery, or if the built-in charger is connected to the mains supply, the truck will automatically shut down the VCM before the charging process starts. The battery must not physically be disconnected from the truck during opportunity charging.

Related read: Forklift Battery Charging Station Power Requirements Explained.

6. Equalising batteries and BDI

The process of balancing the battery, also known as equalising, helps to extend the battery’s life by re-balancing the concentration of electrolytes and ensuring all the cells are charged to their maximum potential. If no balancing process is frequently performed, the battery lifetime and remaining capacity will be reduced over time, making it less sustainable and, in turn, increasing your total cost of operation (TCO).

Battery balancing is carried out via a battery discharge indicator (BDI) which is connected to the battery with a CAN protocol indicating the battery’s SOC and highlighting any potential errors. It’s important to regularly conduct this process (a minimum of once a week) and ensure that the battery is connected to the charger until the BDI shows it’s fully charged for maximum output.

TCM forklift trucks are equipped with an extra battery discharge indicator mounted on the chassis.

7. Cost

No matter how efficient an item is, price always comes into play when deciding on which product to purchase. Whilst Li-ion batteries have a higher acquisition cost than alternatives such as lead-acid, they are more energy-efficient and sustainable meaning your business can make considerable savings in the long run.

Are you ready for 2030? Discover all of the steps you need to take to plan for an energy-efficient right here.

The key benefits of Li-ion batteries

- For material handling organisations looking to adopt lithium-ion batteries, you can welcome a whole host of benefits.

- They consume less energy which contributes to a lower TCO

- They offer fast charging – within one hour – and can also be opportunity-charged, improving efficiency

- Their lifetime is typically 3-4 times longer than other battery alternatives such as lead-acid

- They don’t require maintenance or gassing, reducing cost and downtime

- They produce zero harmful emissions, meaning they are better for the health of the environment and your operators

- They don’t require mid-shift battery changes which increases productivity

- They have decentralised, accessible charging positions

- The internal resistance in the Li-ion battery is much lower than the likes of lead-acid, meaning that Li-ion batteries absorb regenerated energy very efficiently and contribute to extended driving cycles

Related read: Lead-Acid or Lithium-Ion: What's Powering Your Warehouse?

Why TCM’s solutions could be the right choice for your material handling operations

For our forklift trucks, we use NMC chemistry because it offers optimum battery lifetime, performance, and safety levels – for the forklift truck and the operator, too. The low maintenance requirements and the highly efficient performance of Li-ion batteries minimise interruptions, optimise productivity and preserve the truck’s residual value.

TCM forklifts utilise both lead-acid and Li-ion technology as each has its own unique benefits and drawbacks. However, we offer a range of modern Li-ion batteries – and their associated chargers – that are specially designed and tested to operate with the highest level of reliability and utilise the best available technology for optimum performance, safety and durability.

At TCM, we’re committed to helping you find the most efficient and cost-effective battery choice for your operations. For bespoke advice based on your personal circumstance, get in touch with your local TCM dealer here.

.png?width=50)