Share Article

With electrification gaining increasing coverage in the run-up to the 2030 ban on petrol and diesel engines, lithium-ion is a hot topic. However, it might not necessarily be the best solution for your business’ unique operation. Read on to find out why.

Despite the flurry of interest, lithium-ion (Li-ion) is not necessarily the best choice of battery for every organisation. In fact, lead-acid (also known as wet-cell) battery technology is often better suited to operations and can work out to be more cost-effective.

From how wet-cell batteries work and their advantages and disadvantages, to the different types of wet-cell batteries currently available to you on the market, this article will equip you with all the information you need to get started with reducing your costs and optimising your operations.

How does a wet-cell battery work?

Wet-cell batteries — such as lead-acid — contain a mixture of lead (unsurprisingly), lead oxide, plates, and then an electrolyte solution containing a water and acid mix. Hence the term ‘wet-cell battery’.

The plates in wet-cell batteries can be anodes that are attached to a negative battery terminal, or alternatively cathodes attached to a positive battery terminal.

When a load is attached to the terminals, a chemical reaction occurs between the lead, lead oxide, and electrolyte solution (water and acid). This chemical reaction allows electricity to flow through the terminals to the load attached.

When you recharge a wet-cell battery, e.g. lead-acid, the acid returns to the liquid solution to provide more power later on.

But what does this mean for a typical forklift operation? And what are the advantages and disadvantages of wet-cell batteries vs. lithium-ion? Read on to find out.

Discover the right forklift battery to increase your fuel efficiency.

Advantages and disadvantages of wet-cell batteries

Compared to lithium-ion, wet-cell batteries such as lead-acid are up to four times less expensive. If your business is looking for an easy way to cut fleet management costs, lead-acid is a great alternative.

What’s more, lead-acid batteries are also recyclable and therefore produce less waste, helping your business introduce more sustainable practices.

Another key benefit of lead-acid is that it’s widely available. As a result, it’s likely to remain a popular choice for powering electric forklifts for years to come.

Having said this, like most things in life, there are drawbacks. Wet-cell batteries such as lead-acid have a significantly lower battery life than lithium-ion batteries, with an average lifespan of 1,500 cycles. This might not be a problem for businesses running small operations. However, if your business is used to operating 24/7, or is planning to scale up operations ahead of 2030, it’s worth considering what other solutions are available.

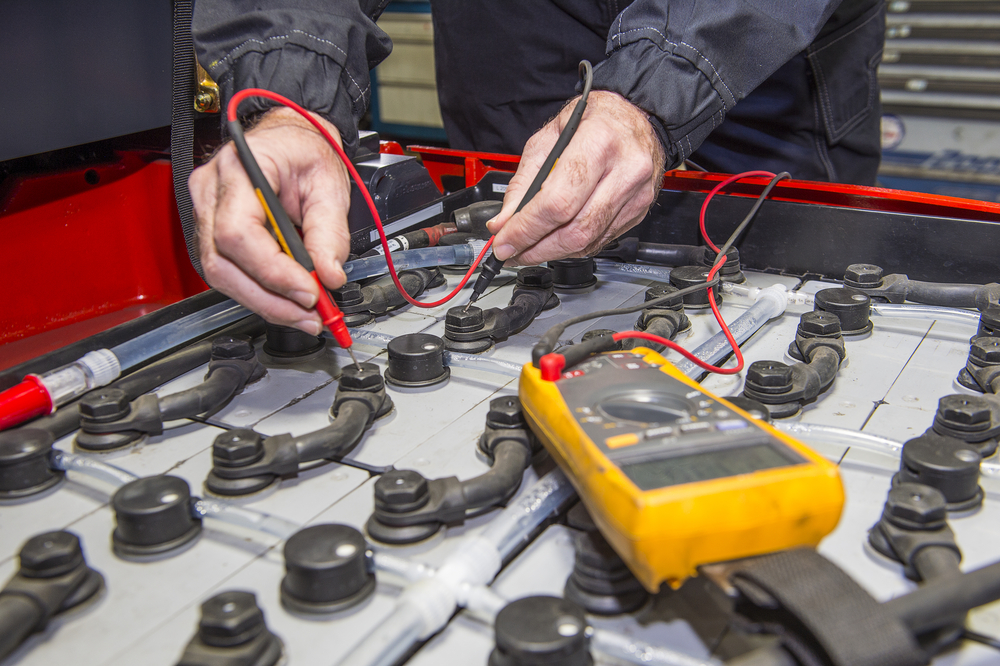

Wet-cell batteries can also degrade by as much as 32% during their lifetime. To combat this, keeping on top of regular maintenance checks is crucial.

Here are four ways you can extend your forklift battery life.

Despite the challenges associated with wet-cell batteries, water topping is easy for operators to carry out manually, and the batteries are straightforward to replace.

Deciding whether to opt for a wet-cell battery solution over lithium-ion will ultimately depend on how intensive your operation and application is. It’s also worth considering whether you could adapt your current shift patterns to accommodate more frequent battery charging breaks.

Related read: Lead Acid or Lithium-Ion: What’s Powering Your Warehouse?

Different types of wet-cell batteries explained

Flooded wet-cell (lead-acid) batteries come in two different configurations: serviceable and maintenance-free.

Serviceable batteries feature removable caps enabling access to the electrolyte. This makes it easy to check and refill the cells with distilled water, known as water topping. On the other hand, maintenance-free batteries don’t provide access to the electrolyte. For this reason, it’s not possible to refill any lost electrolytes.

Flooded wet-cell batteries can be used as either a starting battery or a deep cycle battery. Starting batteries provide short bursts of high energy and feature multiple thin plates with a large surface area. Deep cycle batteries can be used for repetitive deep discharges and feature a limited number of thick plates with a small surface area.

Other types of wet-cell batteries include:

- Starting, lighting, and ignition batteries (SLIs) - great for starting engines

- Deep cycle batteries - can be charged more frequently than SLIs

- Hybrid starting and deep cycle batteries - an SLI and deep cycle hybrid

Discover how TCM Electric Counterbalance Trucks are transforming warehouse operations

Which forklift battery type is best suited to your business?

Deciding between wet-cell and lithium-ion battery technology ultimately depends on numerous factors. To recap, here are some of the key advantages and disadvantages of lead-acid vs. lithium-ion:

| Lead-Acid | Lithium-Ion |

|---|---|

| Cost-effective | Non-polluting |

| Recyclable | No maintenance required |

| Lower battery life | Longer battery life; recharges quickly |

| Can degrade by up to 32% | Higher acquisition cost |

Assessing your operation and application requirements in detail alongside your local TCM dealer will help you to make the right choice for your business.

The 2030 ban on petrol and diesel engines is fast approaching. To start planning for how your operations will make the shift, download our free electrification checklist today.

.png?width=50)