Share Article

.jpg?width=5166&name=shutterstock_1613607151%20(1).jpg)

As soon as you start investigating forklift trucks for your fleet, you'll see a range of different power options. The market used to be dominated by diesel and LPG (liquid petroleum gas), but now robust, high-quality electric-powered forklifts are easily available.

When it comes to deciding which type of power you should use to run your warehouse operations, some key things to consider are the efficiency, safety, and comfort of your operators, as well as the productivity and sustainability of your operations. These factors all contribute to your TCO (total cost of ownership) and, therefore, your profitability.

Are you a warehouse manager looking to determine the best-fit financing solution for your operations and improve your productivity? This free guide might be just what you’re looking for: The Warehouse Manager’s Handbook: How to Identify Your Material Handling Needs

Read on to learn more about the different power options available for your forklift fleet, and which type will prove to be more efficient for your material handling operations.

Electric Forklifts vs. Diesel Forklifts vs. LPG

Diesel: Still the Choice for Heavy-Duty Tasks?

First things first, we all know that fossil fuel emissions contribute to global warming and pollution. For the material handling industry, this means a change in the form of the EU Stage V emissions regulations – By 2030, it will be illegal to sell new gas, diesel, and even hybrid-powered vehicles in the UK.

Whilst this might temporarily disrupt those business operations that utilise non-electric power, the ban will provide numerous benefits such as reduced fuel costs, lower C02 emissions, and improved air quality.

Related read: What Are You Doing to Reduce Your Warehouse’s Environmental Impact: Sustainable Material Handling

This means that businesses are well-advised to consider the makeup of their fleets. At the very least, they should aim for Stage V compliance with the latest clean-air engine technology.

Find out more about the TCM range of Stage V compliant Engine Counterbalance Forklifts here.

Do diesel forklifts provide the best load capacity?

Diesel engines are considered more powerful by some, thought of as being better suited to more arduous and heavier tasks. In the current TCM range, our diesel trucks have a lifting capacity ranging from 1.5 tonnes to 10.0 tonnes. A larger capacity is essential for heavier-duty activities, particularly in manufacturing or logistics.

To compare, the TCM range of electric counterbalance trucks has a lift capacity ranging from 1.4 tonnes to 5.5 tonnes. However, for many material handling operations, this load capacity range will be more than sufficient.

Meanwhile, as technology continues to develop, electric forklifts with greater capacity will become more common. It's already true that today's electric forklifts can do many of the same jobs as diesel, have high-tech designs for robustness, stability and longevity, and are advancing warehouse operations globally.

Related read: How Electric Counterbalance Trucks Are Changing Warehouse Operations

Are diesel forklifts more affordable than electric forklifts?

In terms of affordability, there are pros and cons to diesel. If you are looking for a used forklift, you may find a greater range of diesel trucks available. However, you will need to check their compliance with the latest regulations. This is particularly important if you're buying, not renting or leasing in the shorter term).

Diesel trucks are generally cheaper to buy, but there's a caveat here. Although electric forklift trucks have a higher initial purchase price, they can offer better TCO. This means that they can be cheaper to run over their entire lifespan. They can make your operations run more seamlessly – improving productivity and output – and battery charging, for example, is generally cheaper than diesel refuelling.

Related read: Fleet Management Costs - What is the True Cost of Your Forklift Fleet?

Verdict: why choose diesel-powered forklifts?

Diesel can be great for heavier-duty jobs. The familiarity with diesel technology means it has been easier and cheaper to maintain, but be aware that this is changing as electrification becomes more widely used.

When comparing costs, it's necessary to remember that cost-effectiveness comes down to more than just the initial purchase price – with the enhanced efficiency of electric-powered forklifts, not to mention increased comfort and safety for operators, electric trucks will likely be cheaper in the long run.

Related read: Investing In Electric Forklifts: The Ultimate Guide

Electric avenue: getting on board with the latest in forklift technology

Often thought of as only being suited to indoor use, electric forklifts are very well-suited to external environments.

Limiting your electric forklifts to warehouse tasks means restricting them from other jobs that they’re more than capable of carrying out, Such as cross-docking and unloading lorries, for instance. The (generally) lighter weight of electric forklift trucks means they offer great manoeuvrability whilst retaining impressive lift heights.

Another notable advantage of electric forklifts is their lack of exhaust fumes. Emissions from fossil fuels damage the environment, but they are also harmful to workers. The British Safety Council is among the organisations that have called for limits to exposure to diesel emissions. Investing in electric forklift trucks can help you improve the air quality on your site, protecting your operators by providing a cleaner working environment.

One is that most electric forklifts don't make a lot of noise – certainly much less than a diesel forklift truck. Noise can be an annoyance, but it's also a safety concern when you have multiple appliances and pedestrians moving around your site. A noisy warehouse is not only distracting to those working amongst forklifts, but it can put operators at risk of hearing loss or permanent damage.

Related read: 5 Reasons To Switch From ICE To Electric Forklift Trucks

Are there disadvantages to choosing an electric forklift truck?

Whether you invest in lithium-ion (Li-ion) or lead-acid-powered batteries, electric forklifts need to be charged. This means accounting for downtime, as the truck needs to be stationary during this period. Note that you will need adequate space for dedicated charging areas as well. That being said, Li-ion batteries offer opportunity charging, meaning they can be charged for small amounts of time during the likes of coffee or lunch breaks, and picked up shortly after.

Read more: Forklift Charging Station Power Requirements Explained

It’s often thought that electric forklifts are less suitable for use on outdoor sites, but this is dependent on the type of forklift and the model. Your local dealer can provide you with information about specific features such as weather-resistant exteriors, protected electronics, appropriate warranties, and various other factors that will enable you to invest in an electric forklift that is well-suited to outdoor use.

Above all, the best forklift truck for you is one that works well with your needs and your operations. Electric forklift trucks can provide you with a whole host of opportunities to improve productivity, efficiency and output, making your operations as efficient and cost-effective as possible.

If you’re keen to start investing in the power of electric, take a look at some of the ergonomically-designed, robust models we have to offer:

- Electric counterbalance forklifts

- Electric order pickers

- Electric pallet trucks

- Electric reach trucks

Are you keen to reduce the TCO (total cost of ownership) of your forklift fleet, but unsure where to start? This free guide will help you discover how to calculate your TCO, ensuring you remain competitive, efficient, and profitable.

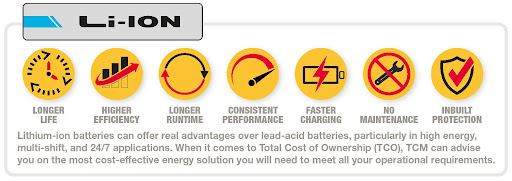

The advantages of Lithium-ion (Li-ion) batteries

As mentioned previously, it's worth knowing that there are different battery options available under the main heading of 'electric'. Li-ion is a highly energy-efficient battery type that charges quickly and doesn't need to be changed mid-shift, increasing productivity.

As with the electric forklift vs. diesel forklift comparison, Li-ion costs more to purchase up front than its more traditional lead-acid counterpart but can provide long-term cost savings. Li-ion doesn't need regular maintenance and there is no risk of damage due to poor maintenance (which is not the same for lead-acid batteries, for which proper care and training are advised due to the risk of hazardous spillages).

Click here to learn what a li-ion battery is, how they work, the benefits they offer, and more.

Verdict: why choose electric forklift trucks?

Electric has a lot to offer. There's a balance to be found in terms of getting your operations ready for an electric fleet, plus the initial outlay. However, you get lower TCO, better environmental impact, and a modern, high-tech forklift that's as capable as a diesel one in most regards.

What about LPG?

You might be thinking of LPG as the middle ground. It's cleaner than diesel, but not as clean as an electric forklift. Much like electric-powered trucks, LPG forklifts create less noise. LPG is also cheaper to buy than a new diesel forklift in many cases.

The downside is that you will likely have higher maintenance costs than an electric forklift (in fact, LPG/gas forklifts can have the highest maintenance costs of all three power types). Although they don't need the regular maintenance of an electric battery, costs do rise with the need for an annual winter service and antifreeze.

You may sometimes see very good travel, acceleration and lift speeds. Of course, speed isn't always an advantage. Safety-first thinking is crucial to protecting your workforce, fleet, site and other assets, and many electric-powered forklifts can operate safely at high speeds – with impressive acceleration – thanks to advanced speed control features.

Electric forklifts vs. diesel forklifts: a final word

There are some tasks best suited to the power a diesel truck offers, and you can find models to meet those needs in the TCM range. However, electric forklift technology continues to advance at a rapid pace, so it's only a matter of time until an electric truck comes out with exactly the capabilities you're looking for (if it doesn't already exist).

While the ban on ICE trucks might seem a long way off, being ready for 2030 won’t happen overnight. Download your free electrification readiness checklist here to see how you can prepare for a more sustainable future.

.png?width=50)